Tool Sharpening and Refurbishing

As a full-service supplier, we offer a comprehensive regrinding and refurbishing service both for original Precimac cutting tools and for competitive brands. All tools serviced are totally controlled by our QA department under the same quality standard as newly manufactured cutting tools. We work closely with each customer to optimize quantities, deliveries and sharpening options.

Utilizing the latest state-of-the-art equipment and methodologies, we provide our customers with the highest quality product and service. We are fully equipped with Walters' CNC tool grinding machines and touchless CNC inspection equipment.

Most tools are resharpened on CNC tool cutter grinding machines and, for original Precimac tools, we use the original manufacturing program and wheel stacks for sharpening to guarantee that the quality of the serviced tool will be equal to new tools.

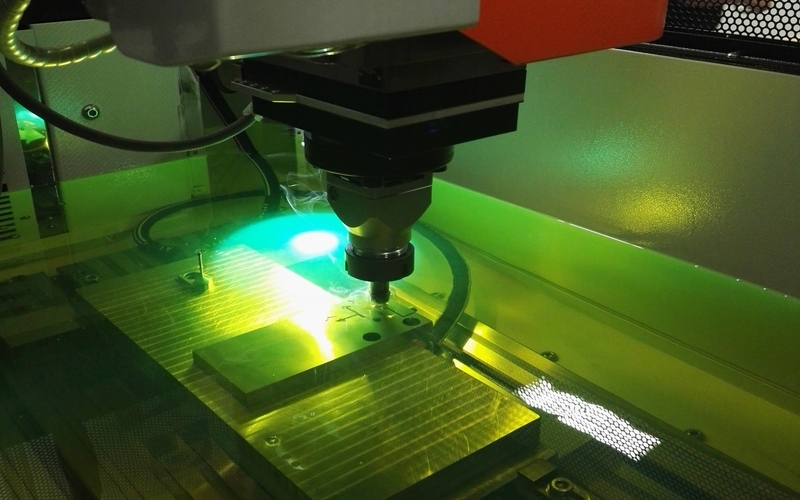

EDM Die Sinking

High precision dies with complex form in bore now can be manufactured with new Argie EDM Die Sinking machine, based on the ultra-high precision electrode manufacturing capability at Precimac.

Next Previous Testimonials

Precimac is always our first choice for cutting tool purchases. I have visited their facility and have seen for myself that they are serious about tools. Their production and inspection equipment and custom engineering functions are very impressive.S.M. – Purchasing Manager

Precimac's attention to quality has meant a very low scrap rate in our production. Their price is always competitive and their turnaround time is fast.W.S. – Manufacturing Technician

Although we have other tool suppliers located much closer to us, we rely on Precimac for cost efficiency, optimum performance and longer tool life.N.T. – Production Manager

We buy 100% of our custom cutting tools from Precimac because they are consistently able to design and supply a unique tool for the application.D.S. – Operations