Precimac’s custom designed drills are manufactured using the latest state of the art automated CNC tool grinders. This allows us to manufacture high-level products at a competitive cost. Our drills are currently being used across the Automotive, Forestry, Aerospace, and Nuclear industries.

- Material: Coolant Through Carbide or HSS

- Coolant supply: Internally fed or solid

- Drill type: spiral flute, straight flute

- Drill point: conventional point, S point, SE point, delta point, etc.

- Coating: all high performance and exotic PVD coatings available

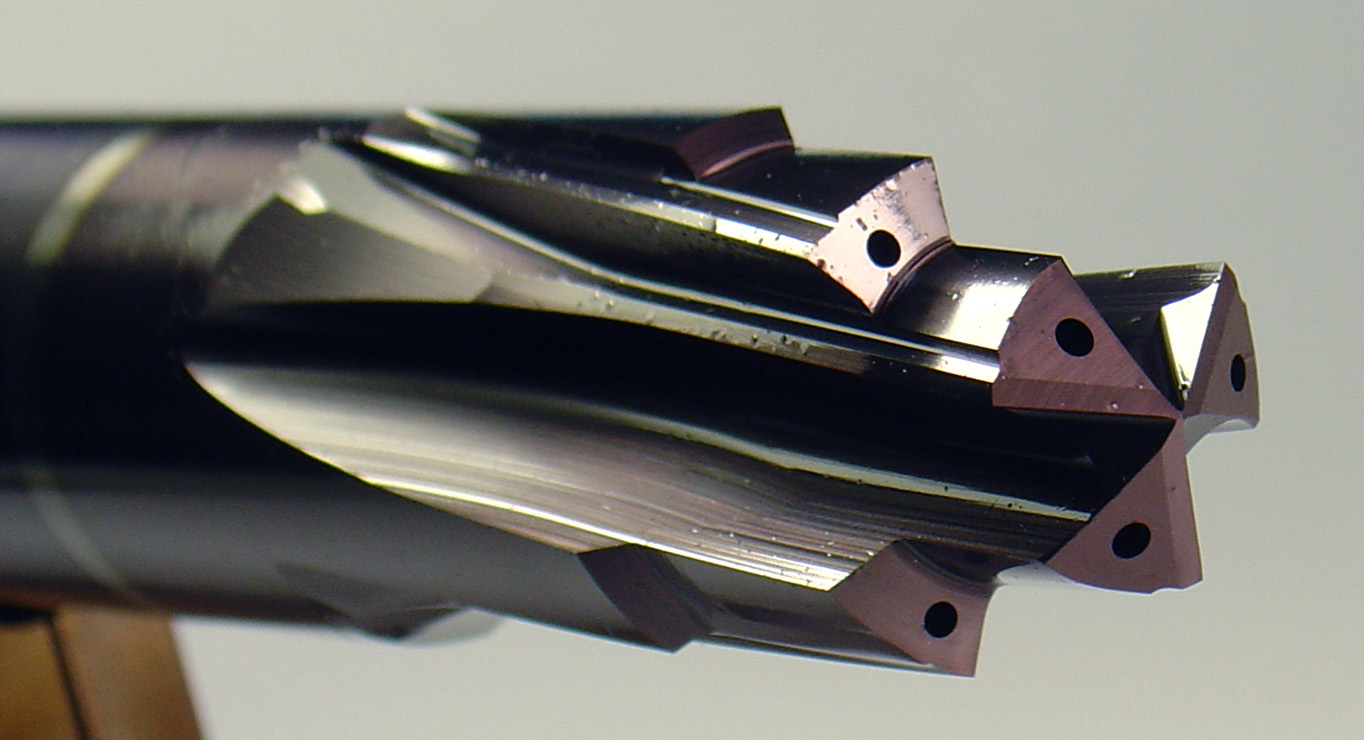

Multi-Step Subland Coolant Through Carbide Drill

Designed specifically for the automotive industry and is capable of drilling multiple features at once.- Made from C-2 grade carbide

- 3 slow-spiral flutes

- Internal coolant supply

- TiAlN PVD coating

- 16mm diameter with a tolerance of +/- 0.002mm

- 30mm Counter bore for sealing surface

- 60 degree chamfer

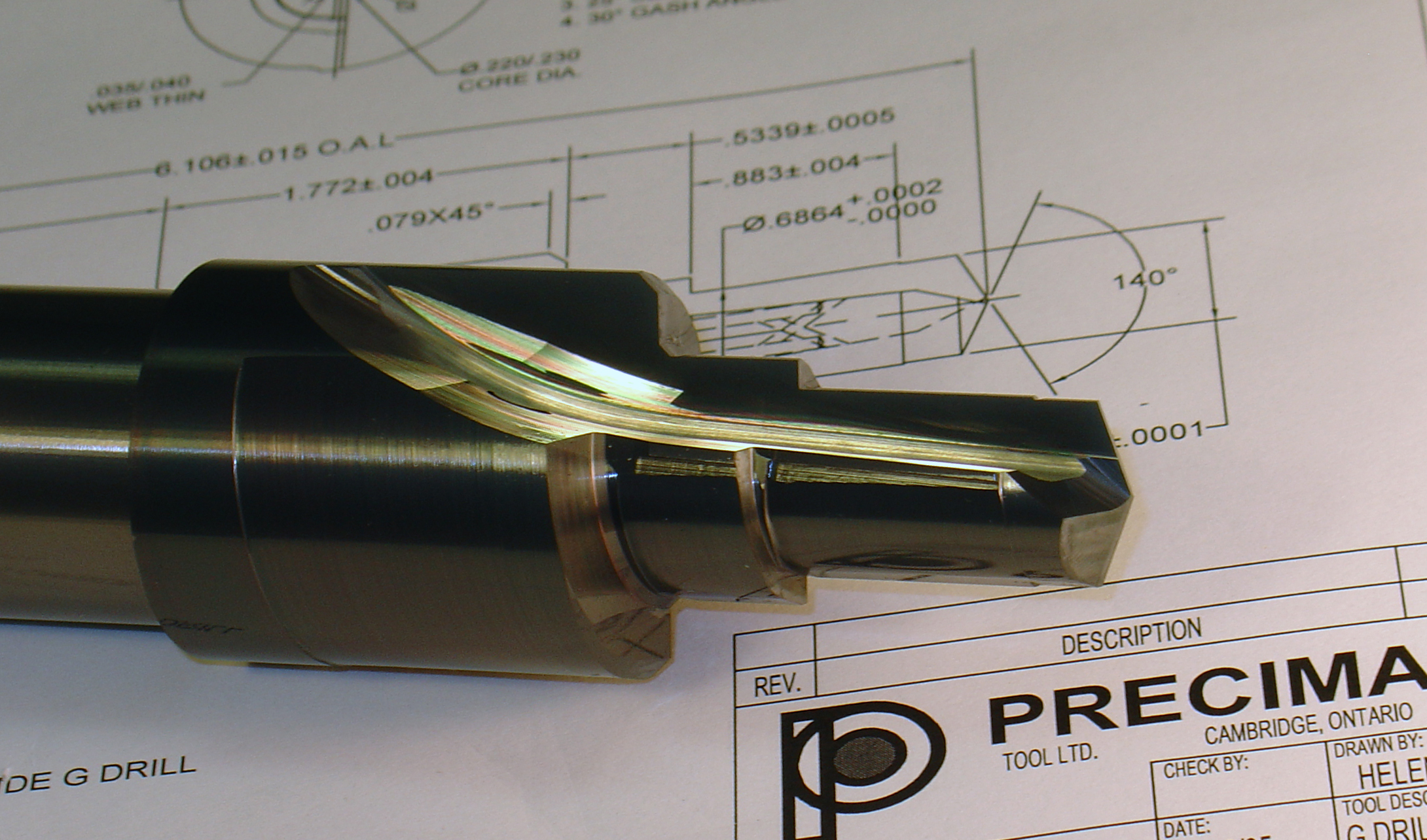

Solid Carbide Multi Step G-Drill

Developed for a special purpose vehicle engine block manufacturing, this drill is capable of drilling, counter-boring, and chamfering.

- Internal coolant supply

- PVD coating for high temperature applications

- Drill diameter with +/- .0002” tolerance

Solid Carbide Subland Step Drill

- Drilling Diameter: 16.5mm x 32mm

- Shank Diameter: 30mm

- OAL: 300mm

- 3 Slow Spiral Flutes

- Subland Design

- TiN PVD coating

Solid Carbide Step Drill

Used in auto engine production line for drilling in cast iron.- Internal coolant supply

- TiAlN coating

S-Point Fast Spiral Double Margin Solid Carbide Drills

Used in automotive engine production for drilling in steel.Resharpening services

As a full-service supplier, we offer a comprehensive regrinding and refurbishing service both for original Precimac cutting tools and for competitive brands. All tools serviced are totally controlled by our QA department under the same quality standard as newly manufactured cutting tools. We work closely with each customer to optimize quantities, deliveries and sharpening options.

Next Previous Testimonials

Precimac is always our first choice for cutting tool purchases. I have visited their facility and have seen for myself that they are serious about tools. Their production and inspection equipment and custom engineering functions are very impressive.S.M. – Purchasing Manager

Precimac's attention to quality has meant a very low scrap rate in our production. Their price is always competitive and their turnaround time is fast.W.S. – Manufacturing Technician

Although we have other tool suppliers located much closer to us, we rely on Precimac for cost efficiency, optimum performance and longer tool life.N.T. – Production Manager

We buy 100% of our custom cutting tools from Precimac because they are consistently able to design and supply a unique tool for the application.D.S. – Operations