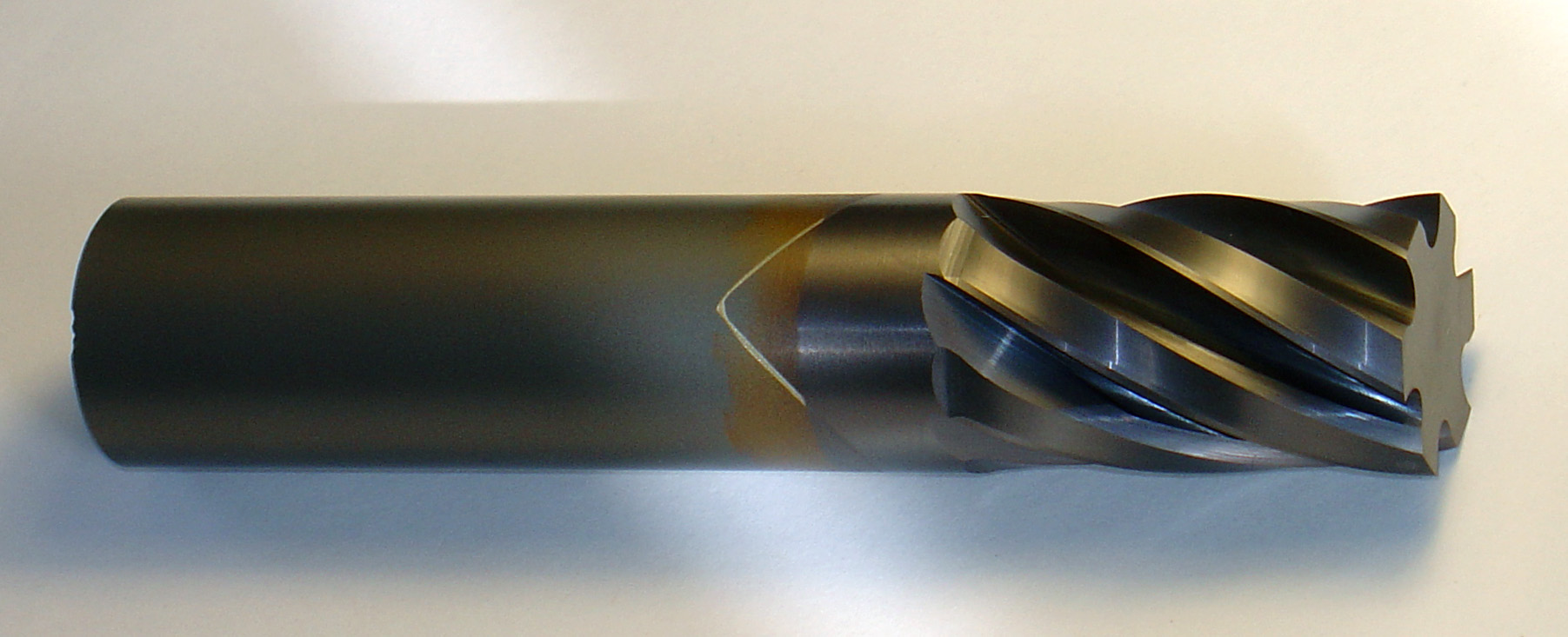

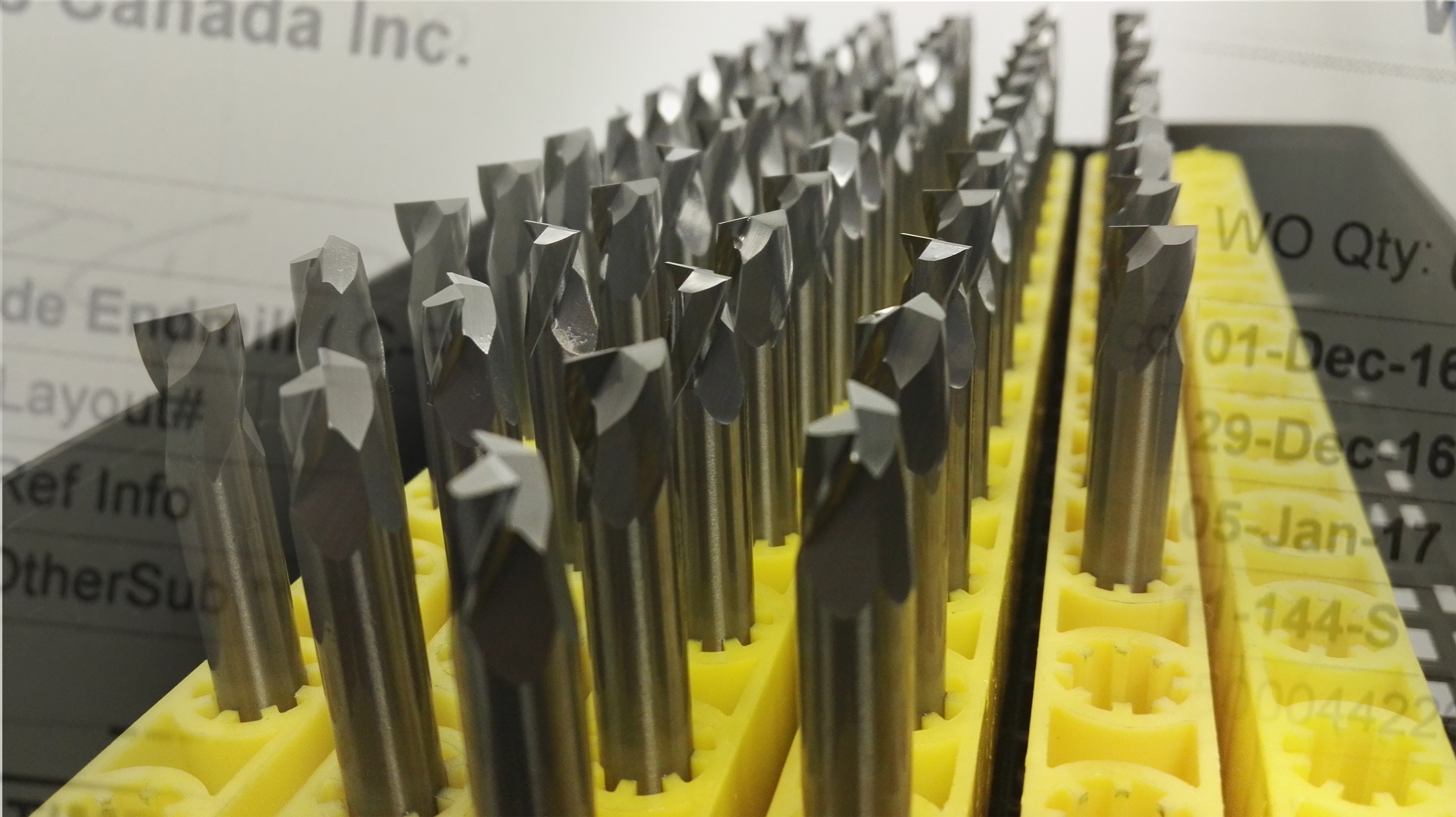

We supply a wide range of carbide endmills for both roughing and finishing operations. These can be manufactured as solid carbide or coolant through. The number of flutes and types of end features can be customized for the specific needs of our customers.

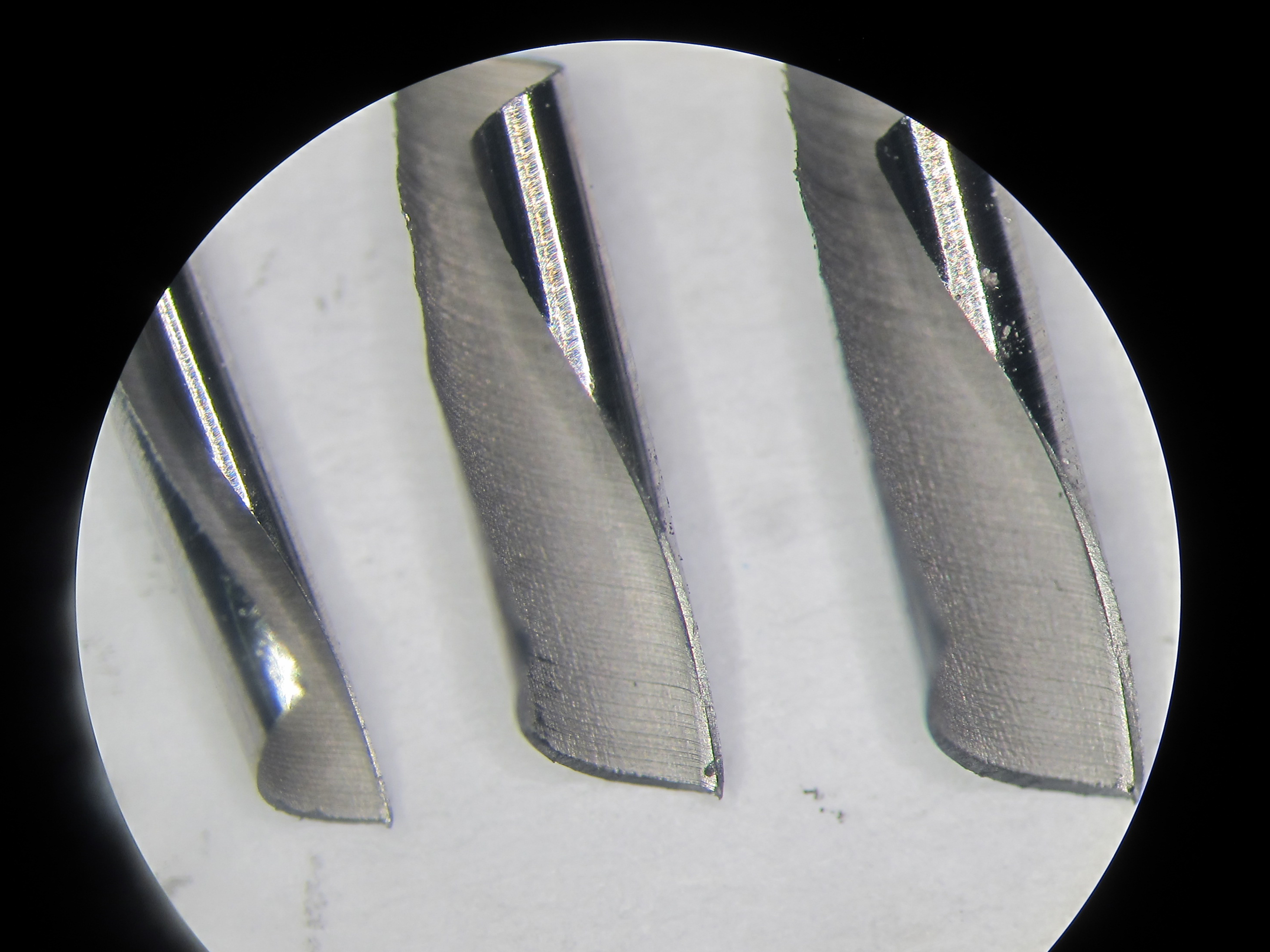

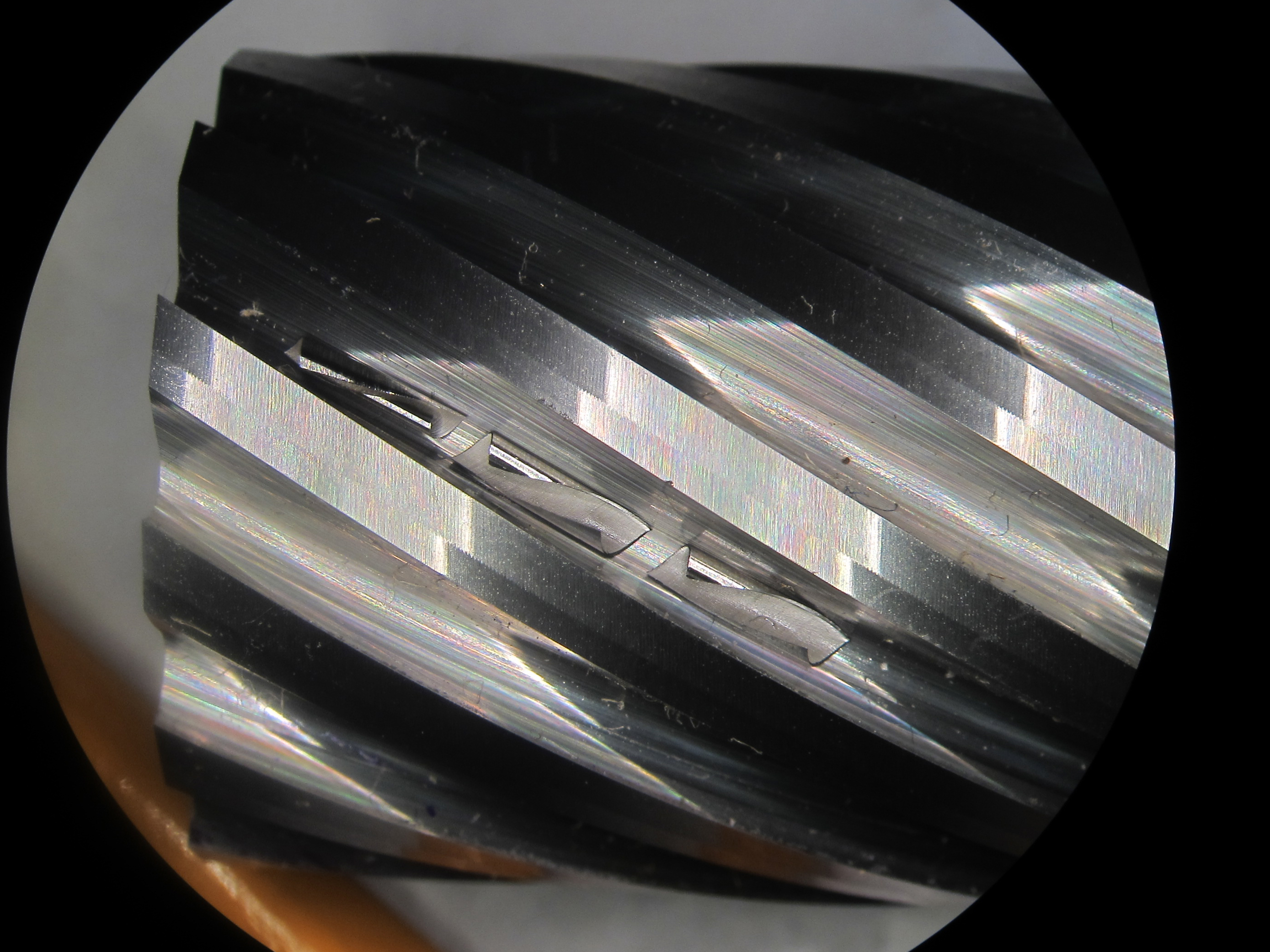

(photo taken under microscope)

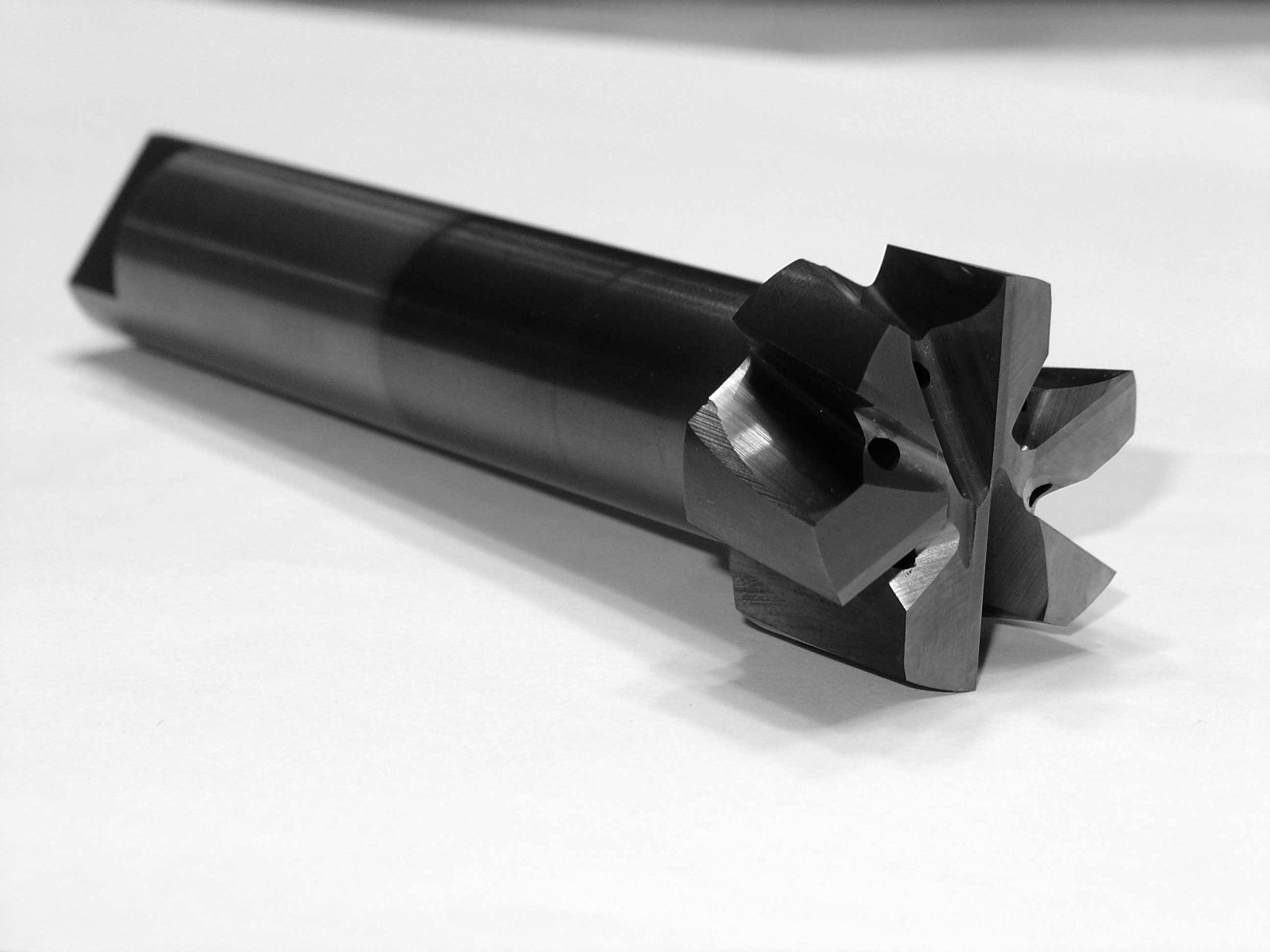

Solid Carbide Side Milling Cutter

This endmill is manufactured to cut through hardened materials. The V-Brazed feature allows for a replaceable cutting head, thereby reducing tooling costs.

Threaded Shank Endmill

Solid Carbide Spot Cutter

Solid Carbide Step Endmill

Solid Carbide Interpolating Tool

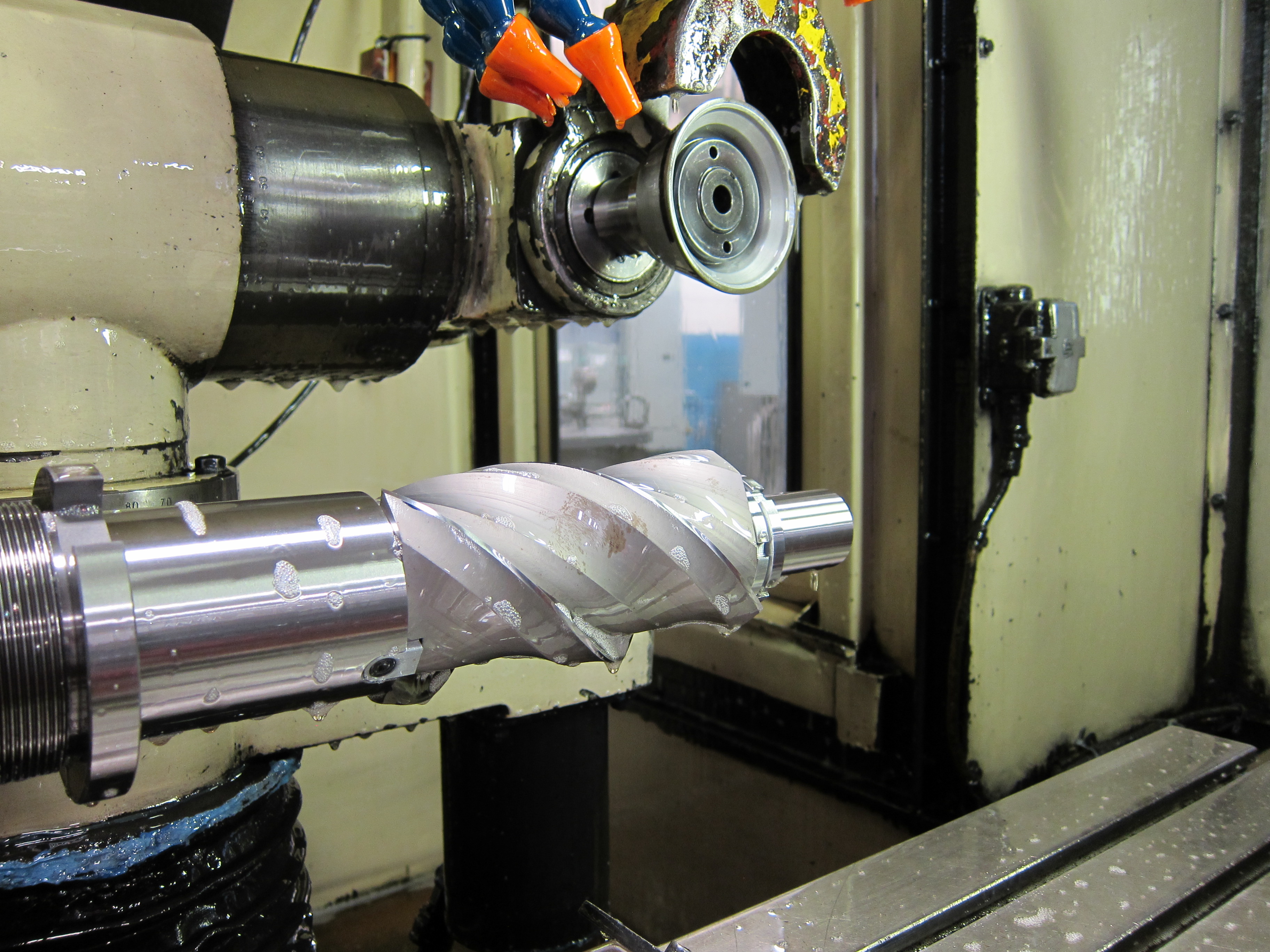

Special Milling Cutter with CAT50 Holder

Machining soft non-ferrous material (i.e. gold, silver).

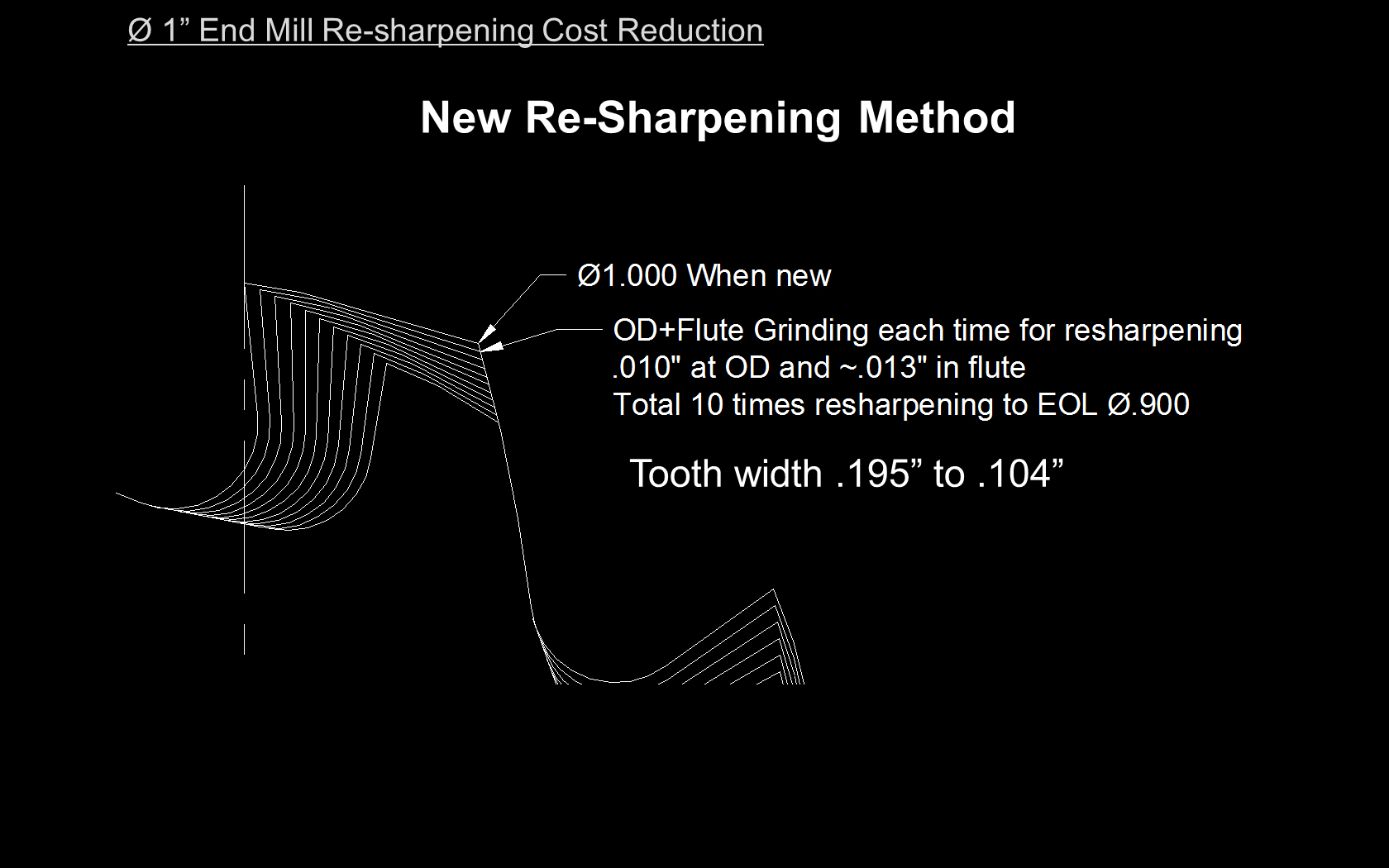

Resharpening services

As a full-service supplier, we offer a comprehensive regrinding and refurbishing service both for original Precimac cutting tools and for competitive brands. All tools serviced are totally controlled by our QA department under the same quality standard as newly manufactured cutting tools. We work closely with each customer to optimize quantities, deliveries and sharpening options.

Next Previous Testimonials

Precimac is always our first choice for cutting tool purchases. I have visited their facility and have seen for myself that they are serious about tools. Their production and inspection equipment and custom engineering functions are very impressive.S.M. – Purchasing Manager

Precimac's attention to quality has meant a very low scrap rate in our production. Their price is always competitive and their turnaround time is fast.W.S. – Manufacturing Technician

Although we have other tool suppliers located much closer to us, we rely on Precimac for cost efficiency, optimum performance and longer tool life.N.T. – Production Manager

We buy 100% of our custom cutting tools from Precimac because they are consistently able to design and supply a unique tool for the application.D.S. – Operations