Precimac has been supplying solid carbide slotting and slitting saws across North America for decades. With new developments in materials, carbide has mostly replaced traditional HSS slotting/slitting cutters. We will assist you and perfect a design best suited for your special application.

A 3" Diameter Carbide Slotting Cutter used in the forestry industry.

This is a special form slotting saw used to cut a groove on a 4140 alloy steel part in high-volume production. This saw features a form relieved OD clearance to maintain a consistent clearance angle after sharpening. It has dimensional and geometric tolerances of .0001", a full radius tooth profile, and a high-quality PVD coating.

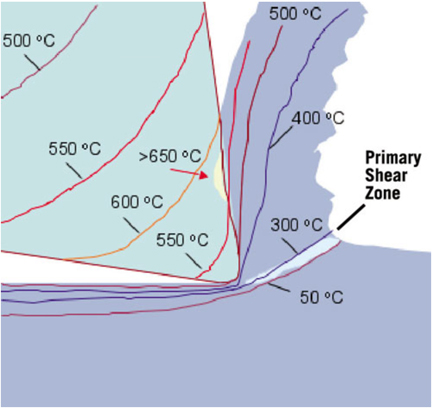

Often, the overall performance is reliant on many factors such as the coolant, the cutting speed and chipload; not just the tool itself.

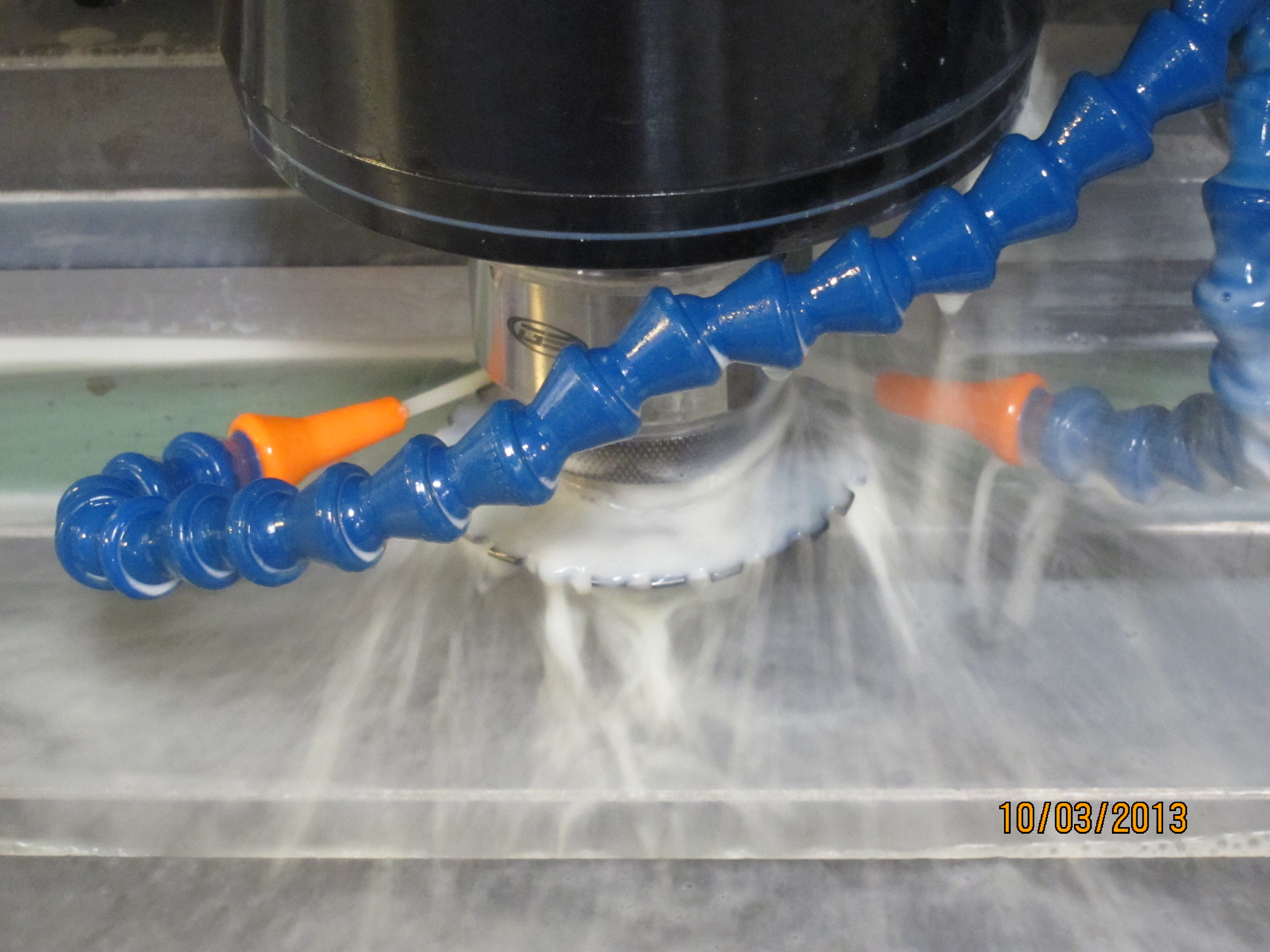

We perform in-house testing with our saws to determine the ideal parameters for optimal performance.

These "sheet metal" like chips are not ideal for optimal performance. Ideally, the chips should form into rings as seen in the picture below. By utilizing the full potential of the tool, it is possible to double the chip load and therefore, double your productivity without any extra investment.

The coloured rings on the right occur due to excessive heat from an insufficient coolant supply. The ring on the left is ideal as it represents an adequate coolant supply, which ensures the cutting edge does not overheat

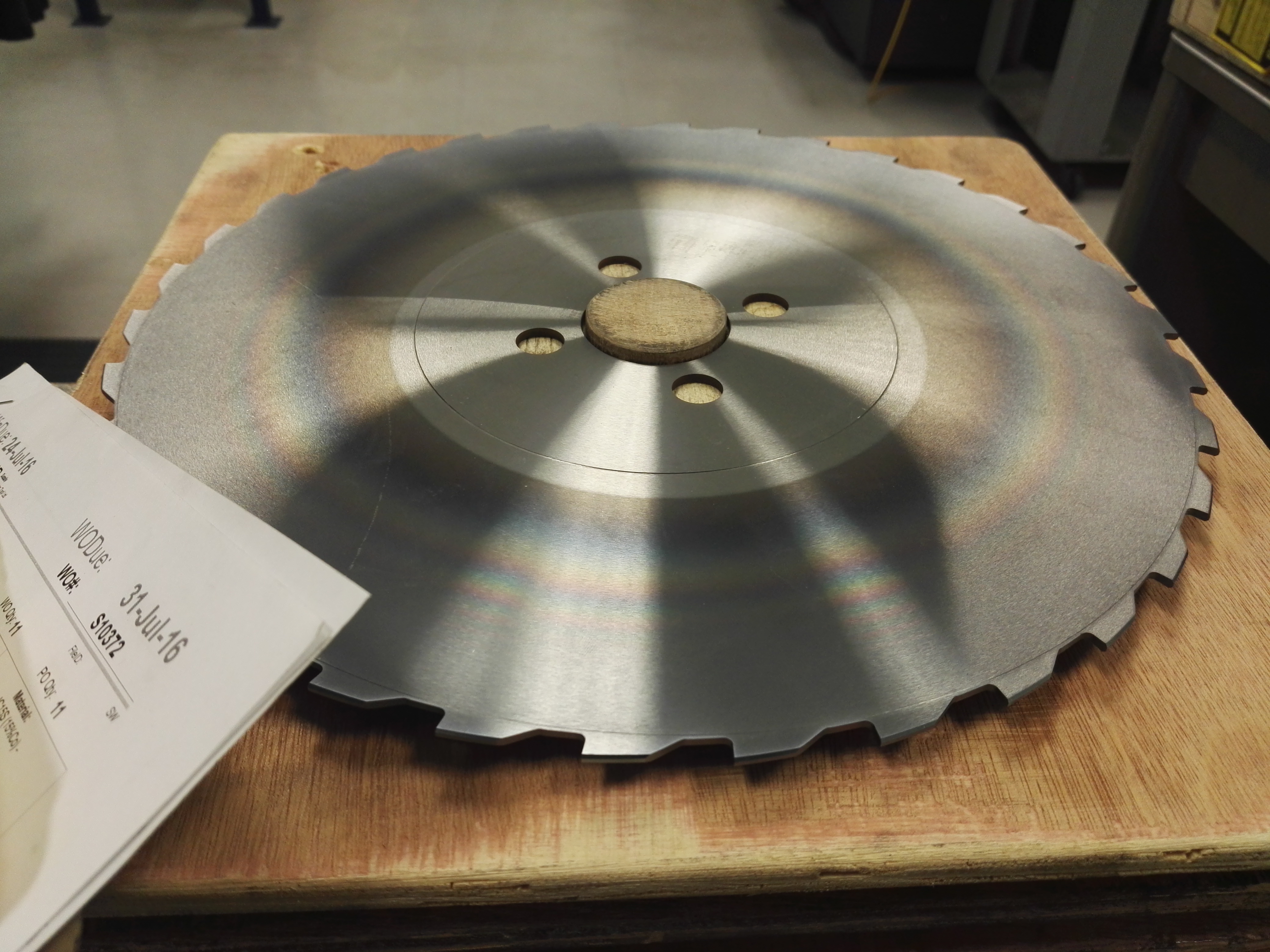

This 11” dia. x .080” thick “solid carbide” saw was designed and manufactured by Precimac to satisfy a deep slotting operation.

10" Diameter Carbide Slitting Saw

This is an 80-tooth, 8mm thick saw that is used in the production of cast iron manifolds. It features a TiALlN PVD coating.

This is a 4” HSS cutter that we supply to the nuclear energy industry.

This industry has very high quality demands and is a testament to Precimac's ability to deliver consistent results across all batches of our products.

3" Diameter Chamfering Saw

Used to establish chamfers in the grooves cut by the slotting saw above. These are manufactured from carbide and receive a TiCN coating. The chamfering saw, used together with the slotting saw, provide high-precision machining and optimal tool life. Using carbide material instead of HSS allows the tool to perform substantially better.

Next Previous Testimonials

Precimac is always our first choice for cutting tool purchases. I have visited their facility and have seen for myself that they are serious about tools. Their production and inspection equipment and custom engineering functions are very impressive.S.M. – Purchasing Manager

Precimac's attention to quality has meant a very low scrap rate in our production. Their price is always competitive and their turnaround time is fast.W.S. – Manufacturing Technician

Although we have other tool suppliers located much closer to us, we rely on Precimac for cost efficiency, optimum performance and longer tool life.N.T. – Production Manager

We buy 100% of our custom cutting tools from Precimac because they are consistently able to design and supply a unique tool for the application.D.S. – Operations